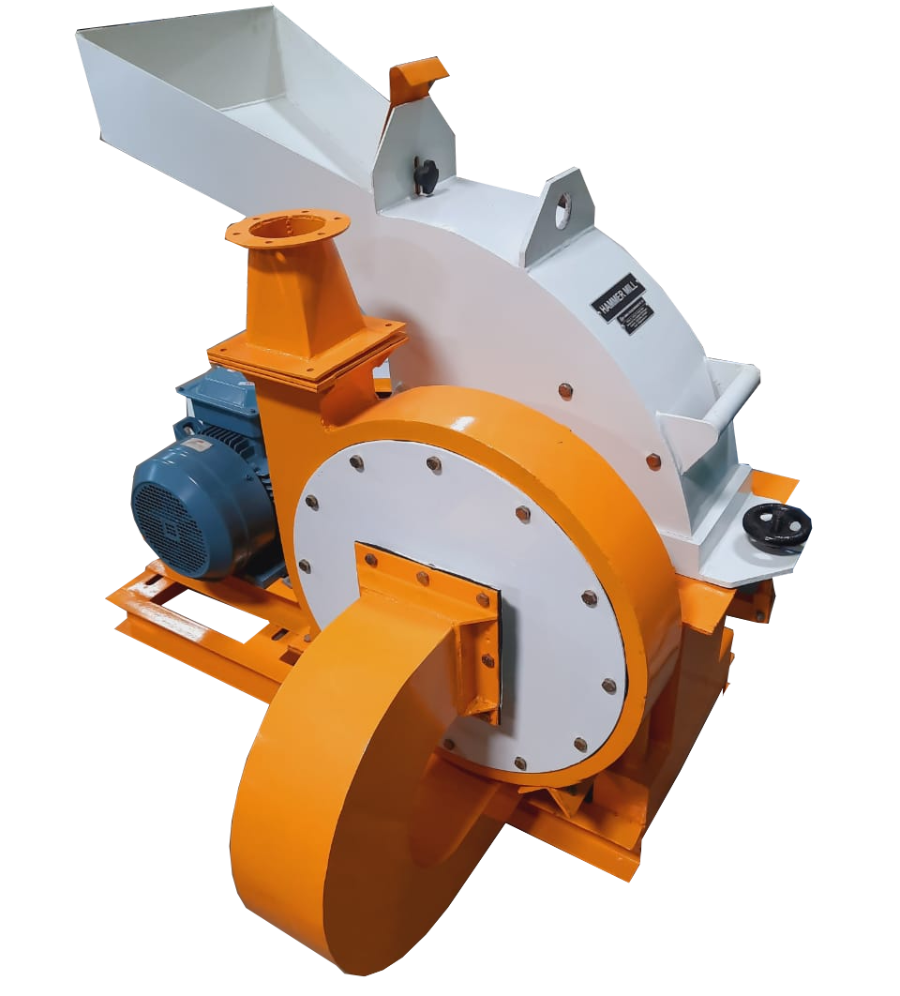

HAMMER MILL

HAMMER MILL

The process of size reduction (for feed material) is carried out by rectangular pieces of hardened steel that rotate inside the chamber at a high speed, striking the material to be milled with a powerful force. These radially swinging hammers (from the turning central shaft) help crush/grind the feed material by moving at a high angular velocity, eventually grinding the material into different sizes.

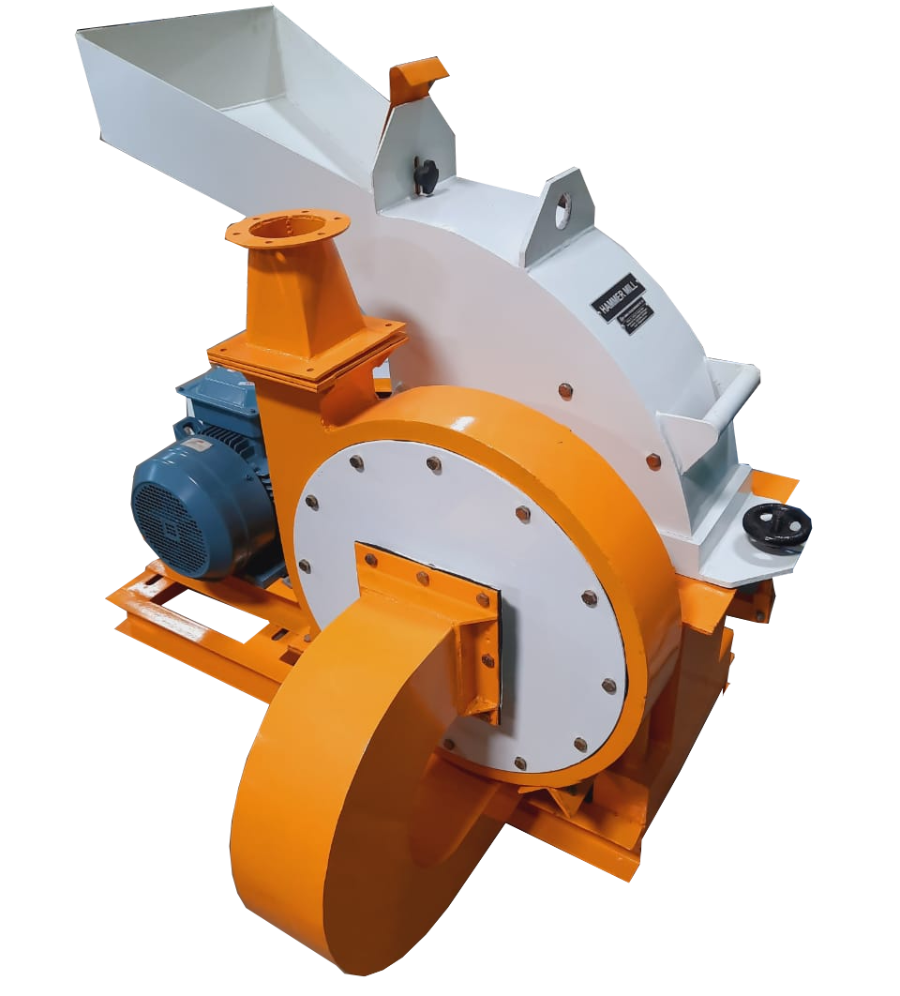

HAMMER MILL

The process of size reduction (for feed material) is carried out by rectangular pieces of hardened steel that rotate inside the chamber at a high speed, striking the material to be milled with a powerful force. These radially swinging hammers (from the turning central shaft) help crush/grind the feed material by moving at a high angular velocity, eventually grinding the material into different sizes.

- It is a cost-effective machine with low energy requirement for operation, which saves costs.

- It can grind/crush different types of materials at high angular velocity.

- Its reduction ratio and capacity are high, irrespective of whether it is used for primary, secondary, or tertiary grinding.

- Size reduction of material happens dynamically. It is especially great for brittle material.